Understanding the Manufacturing Process Behind GRP Grating

Introduction

GRP Grating has become an essential material across various industries due to its exceptional strength, corrosion resistance, and long-term durability. As industries increasingly seek lightweight yet robust alternatives to traditional steel structures, GRP Grating continues to stand out. Understanding how GRP Grating is manufactured not only helps buyers make informed decisions but also highlights why this material performs so well in demanding environments. This article provides a comprehensive and professionally structured breakdown of the complete manufacturing process behind GRP Grating, offering insights into its composition, design, production methods, and quality assurance procedures.

What Is GRP Grating?

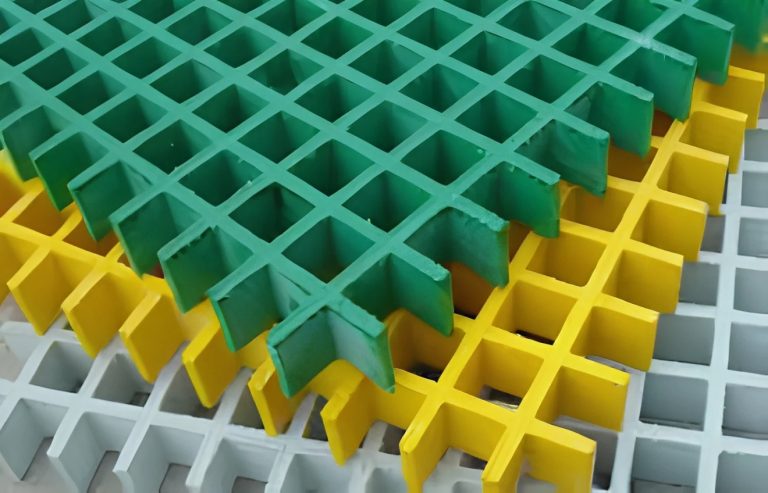

GRP Grating (Glass Reinforced Plastic Grating) is a composite material made from fiberglass and resin. The combination of these materials results in a lightweight yet structurally powerful solution that is widely used for flooring, walkways, platforms, and industrial applications.

Key Components Used in GRP Grating

- Fiberglass: Provides strength and reinforcement.

- Resin: Offers chemical and environmental resistance while binding the fiberglass.

- Additives: Improve fire resistance, UV protection, color, and durability.

Why GRP Grating Is Manufactured

The demand for GRP Grating has grown because it offers unique advantages over steel, aluminum, and wooden alternatives. Industries choose GRP Grating for various reasons:

- Non-corrosive performance in harsh environments

- High strength-to-weight ratio

- Minimal maintenance requirements

- Long operational lifespan

- Safety features such as anti-slip surfaces

Understanding how GRP Grating is produced sheds light on why it offers such superior performance.

Overview of the GRP Grating Manufacturing Process

The manufacturing of GRP Grating involves several carefully controlled phases. Each stage is designed to ensure structural reliability, performance consistency, and compliance with industrial standards.

Main Manufacturing Stages

- Material preparation

- Mold setup and configuration

- Resin mixing and formulation

- Fiberglass placement

- Resin application

- Curing and hardening

- Demolding

- Finishing

- Quality inspection

Below, each stage is explained in detail to give you a complete understanding of how GRP Grating is created.

Stage 1: Material Preparation

Before production begins, all raw materials are selected based on the type and grade of GRP Grating being manufactured. This includes the right fiberglass type, the correct resin formula, and the appropriate additives.

Fiberglass Selection

The fiberglass used in GRP Grating is typically E-glass, chosen for its strength, durability, and thermal stability. The strands may come in different forms—mat, roving, or woven fabric—depending on the desired load-bearing capacity.

Resin Formulation

Polyester, vinyl ester, or phenolic resins can be used. The type of resin affects corrosion resistance, fire retardancy, and chemical stability. Since GRP Grating often operates in harsh environments, resin preparation is critical.

Stage 2: Mold Setup and Configuration

GRP Grating is normally produced using large heated molds that shape the material into the finished grating pattern. Molds consist of a steel frame containing a grid layout, which determines the size and spacing of the bars.

Mold Preparation Steps

- Cleaning and inspecting the mold

- Applying release agent to ensure easy removal

- Configuring mesh size and bar thickness

The accuracy of mold setup ensures that the final GRP Grating complies with dimensional standards.

Stage 3: Resin Mixing and Formulation

In this stage, operators prepare the resin mixture used to create the base of GRP Grating. The mixture includes the primary resin, catalyst, pigments, fire retardants, and UV stabilizers.

Importance of Correct Resin Ratios

The strength and durability of GRP Grating depend heavily on the precision of resin formulation. Incorrect ratios can lead to brittle grating, reduced load capacity, or improper curing.

Stage 4: Fiberglass Placement

Fiberglass reinforcements are placed into the mold following a specific pattern. This pattern defines the overall strength structure of the GRP Grating.

Layering Techniques

The fiberglass may be layered in multiple directions or sequences to enhance tensile strength and load distribution. Each layer plays an important role in forming the final structure.

Stage 5: Resin Application

Once fiberglass is positioned, the resin is poured or infused into the mold, ensuring full saturation of the fiberglass.

Ensuring Complete Resin Saturation

Proper resin penetration ensures that there are no air bubbles or voids within the GRP Grating, which could weaken the final product. Automated resin injection systems are often used for consistent distribution.

Stage 6: Curing and Hardening

Curing transforms the resin-saturated fiberglass into solid GRP Grating.

Heat and Pressure Curing

The mold is heated to activate chemical reactions within the resin. Depending on the resin type and end-use requirements, different temperatures and curing durations may be used. During this stage, the mixture hardens and forms a solid, durable structure.

Why Curing Matters

Proper curing results in:

- High load-bearing capacity

- Chemical resistance

- Dimensional stability

Incorrect curing may compromise the integrity of the GRP Grating.

Stage 7: Demolding

Once fully cured, the GRP Grating is removed from the mold.

Steps in Demolding

- Cooling the mold

- Carefully lifting the grating to avoid cracks

- Inspecting for early signs of defects

Demolding must be done gently, as rough handling can damage the newly formed GRP Grating.

Stage 8: Finishing and Surface Treatment

After removal, the GRP Grating is trimmed, cut, and finished to meet required specifications.

Typical Finishing Processes

- Edge trimming

- Surface smoothing

- Application of anti-slip coatings

- Cutting panels to standard or custom sizes

These finishing touches enhance the appearance, performance, and safety features of GRP Grating.

Stage 9: Quality Control and Testing

Before being delivered to customers, GRP Grating undergoes rigorous testing.

Tests Performed

- Load testing

- Chemical resistance testing

- Flame retardancy testing

- Dimensional accuracy inspection

Quality control ensures that every piece of GRP Grating meets industry and safety standards. Manufacturers often follow ISO, ASTM, and EN guidelines to guarantee product reliability.

Types of GRP Grating Based on Manufacturing Methods

The manufacturing process varies slightly depending on the type of GRP Grating being produced.

Molded GRP Grating

Molded GRP Grating is produced in a single piece using the processes described above. It is known for its impact resistance and uniform strength in both directions.

Advantages

- Excellent corrosion resistance

- Ideal for heavy-duty environments

- High slip resistance

Pultruded GRP Grating

Pultruded GRP Grating is manufactured by pulling fiberglass rods through a resin bath and forming them into a grating shape.

Advantages

- Higher load-bearing capacity

- Longer span capability

- Lightweight and rigid

Both types of GRP Grating have unique strengths, and manufacturers choose the method based on application needs.

Applications of GRP Grating Across Industries

GRP Grating is used in many sectors due to its durability and performance.

Industrial Applications

- Chemical plants

- Offshore platforms

- Oil & gas refineries

Commercial Applications

- Walkways

- Platforms

- Maintenance decks

Public Infrastructure

- Drain covers

- Bridges

- Stair treads

Its corrosion resistance makes GRP Grating particularly valued in environments exposed to chemicals, moisture, and saltwater.

Why the Manufacturing Process Matters

Understanding how GRP Grating is made explains why it performs better than traditional alternatives. The careful combination of fiberglass reinforcement, resin formulation, curing techniques, and quality testing contributes to its exceptional long-term performance.

Key reasons to understand the process:

- Helps buyers evaluate product quality

- Ensures the right grating is selected for the right application

- Highlights the durability provided by composite manufacturing

FAQs About GRP Grating

How is GRP Grating manufactured?

GRP Grating is produced through pultrusion or molding, combining fiberglass with resin for strength and durability.

Does the manufacturing process affect GRP Grating quality?

Yes, precise control of resin formulation and fiber alignment ensures consistent performance and long-lasting GRP Grating.

Can GRP Grating be customized during production?

Absolutely, size, shape, and load capacity can be tailored during manufacturing to meet specific project requirements.

Conclusion

The manufacturing process behind GRP Grating is detailed, precise, and highly engineered to produce a material capable of withstanding some of the harshest environments. From raw material selection to curing, molding, and quality control, each stage contributes to the strength, safety, and longevity that GRP Grating is known for. By gaining insight into these processes, buyers and industry professionals can better appreciate why GRP Grating remains one of the most reliable and versatile solutions across a wide range of applications.